Mohawkite is a rare copper mixture found in only one place, on the Keweenaw Peninsula of Michigan. It was first discovered around 1900 in the Mohawk copper mine, which is where it got its name.

Colors & Patterns

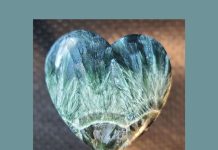

Mohawkite is one of those beautiful materials that stand out for its desirable natural metallic designs, much like Josephine’s Crown, or gold in quartz.

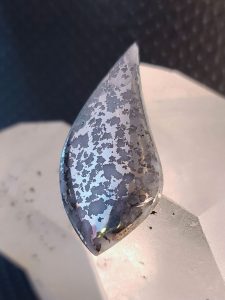

Its colors range from metallic yellow to grey, and at times it has a blueish-green tarnish. The coloring comes from its two main ingredients, algodonite, and domeykite, both arsenic-rich copper minerals. Most have a beautiful spiderwebbing pattern, while other nuggets can be solid metallic. The most desirable pieces used in lapidary are the mixed metallics in quartz.

Where to Find Mohawkite

Mohawkite is becoming quite scarce to find, but it still tends to occasionally appear at shows or online sales. Much of what you find is very visible on the outside, being able to see if it has a good mixture of host stone with copper minerals, or if it’s pure algodonite & domeykite.

Safety First

Safety First

Before working with this material, be prepared to use all protective measures when cutting and cabbing, as this type of material contains arsenic. Most lapidaries use N95 masks and eye protection. I prefer to use a mask with a high rating of protection, using a P100 half-face mask.

Be sure to always have water running on your machines at all times, this type and other materials with potentially dangerous ingredients should never be cabbed dry, allowing the dust to go airborne. Another tip would be to always consider showering right after, even though you may have water running on the machines, the mist that gets generated will still have microparticles that can collect in your hair.

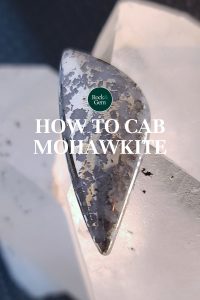

Cabbing Mohawkite

Cabbing Mohawkite

When starting out cutting slabs, there really isn’t any correct direction, as it will yield a continuous pattern throughout the stone, whether solid metallic or mixed with quartz matrix.

The cabbing process is relatively simple. Mohawkite isn’t very hard, so you can quickly shape and dome your cabs on the 80-grit wheel, and then smooth it all out on a 140-soft resin or 220-steel wheel.

The main portion of your work will be done at the 280 grit stage. This is where you will take your time to make sure there are no flat spots or any remaining scratches before moving on.

You may see micro swirls in the metallic areas which are okay. This will get removed as you go along. After running through your typical setup, you should be able to complete your cab at the 14k grit wheel, leaving a beautifully polished cab.

At this point, you can add additional polishes with Zam polishing compounds, or jewelers rouge. Some lapidaries like to be a little more protective and seal the cab afterward to keep it from tarnishing and protect it from the arsenic within. Most of the time if the stone is further designed by a silversmith or wire wrapped, it shouldn’t be much of an issue as it won’t have any contact with the skin of the person wearing it. Others like to take that added caution and seal it, with either lacquer, 330 epoxy, or even Opticom.

This story about mohawkite appeared in Rock & Gem magazine. Click here to subscribe. Story by Russ Kaniuth.