Cold Mountain thundereggs come from the Sierra Mountains between the cities of Aguascalientes and Zacatecas, Mexico.

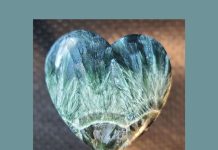

When you hear the word thundereggs, most people quickly associate them with baseball size geode-type stones filled with agate. In this case, this material is just a slight bit different. This material looks like a bunch of golf balls and marbles all clustered together in a big muddy clump! Once you cut one open though, you will see all the beauty in it.

Cold Mountain Thundereggs vs. Butterfly Jasper

This material resembles Butterfly jasper quite a bit but certainly has its own beautiful characteristics. The rhyolite is full of earthy colors, and the orbs have fractal patterns with rivers of agate running through them.

This material resembles Butterfly jasper quite a bit but certainly has its own beautiful characteristics. The rhyolite is full of earthy colors, and the orbs have fractal patterns with rivers of agate running through them.

When buying rough, you won’t really know what’s inside until you cut it. You can look for pieces with more orbs showing on the outside, and some with possible pieces broken off so you can see the patterns inside. Each piece will always be different, there will be no two slabs the same.

When cutting slabs, there is no real direction to clamp the stone into the saw for a certain pattern, so position the material in the vice that best fits the saw. Because of the awkward round shapes the rough comes in, sometimes using wood wedges to secure the stone in the vice is advisable.

Testing for Fractures Pays Off

Once your slabs are cut, and it’s time to draw out your cab patterns, test each slab first for possible fractures that will break apart. It’s better to find out now than later down the line that there is a fracture. Flexing the slab in your hands or tapping it lightly against the bench will usually tell you if the slab will be stable or not. The fractal patterns, orbs and rivers of agate will give you all sorts of abstract patterns to work from to create gorgeous designs.

Cabbing this material is generally pretty easy, it’s really not much different from any other rhyolite or jasper. I would guess the hardness on the Moh’s scale to be around a 5.5, so start on an 80 grit to shape your preform and start your dome. Though there are different minerals involved in the material, they don’t differ too much in hardness so you shouldn’t have too much trouble with undercutting, but I would suggest smoothing out the dome and removing as many of the scratches on the 220 grit wheel as possible.

rhyolite or jasper. I would guess the hardness on the Moh’s scale to be around a 5.5, so start on an 80 grit to shape your preform and start your dome. Though there are different minerals involved in the material, they don’t differ too much in hardness so you shouldn’t have too much trouble with undercutting, but I would suggest smoothing out the dome and removing as many of the scratches on the 220 grit wheel as possible.

From there, let the 280 grit wheel do the work, smooth out the cab, and make sure to remove any remaining scratches at this stage before moving on. By the time you reach the 600 grit wheel, you will see how quickly the rhyolite starts to polish up. Continue the cabbing process as usual, most might finish at the 14k grit wheel, which will leave you with a nice glossy polish. However, if you have a 50k grit wheel in your setup, you will achieve a mirror polish.

Skip Polishing Compounds When Fissures Are Present

Since this material contains agate and is comprised of several minerals, you might find small drusy vugs within the agate or small fissure openings along some of the patterns where they bud up against each other, this is why I wouldn’t suggest using polishing compounds. The compounds will fill these areas in and make it very tough to get it out.

The final polish usually looks best from what you’ve achieved on the wheels. This material and many other Mexican stones are readily available through the J H Kalmore Company on Facebook.

This What to Cut column about Cold Mountain thundereggs previously appeared in Rock & Gem magazine. Click here to subscribe! Story and photos by Russ Kaniuth.