By Bob Rush

For many years, I have worked with synthetic quartz, mostly utilizing it for the top layer in a triplet cabochon, but also putting it on both the top and bottom, depending on what I want the cab to look like. I like it because it is always crystal clear, fracture-free, and readily available at a reasonable cost. It is relatively easy to cut and polish, but you must use caution in your cabbing activities to ensure it doesn’t get overheated, or it will fracture.

Making the Most of Rejects

The synthetic quartz bars that are available for lapidaries are the rejects from the electronics industry. They are made for use as the frequency control component in almost every electronic device manufactured. The quartz bar that is grown must have a structure that exactly meets very rigorous standards, and not all of them do. The crystal bars do not resemble the standard six-sided crystal shapes that form naturally.

A seed crystal is formed by cutting a natural crystal horizontally, and the seed is suspended vertically in the crystal-growing chamber. The crystal grows sideways from this seed, rather than the lengthwise growth found in nature. Doing it in this manner can significantly speed up the growing process.

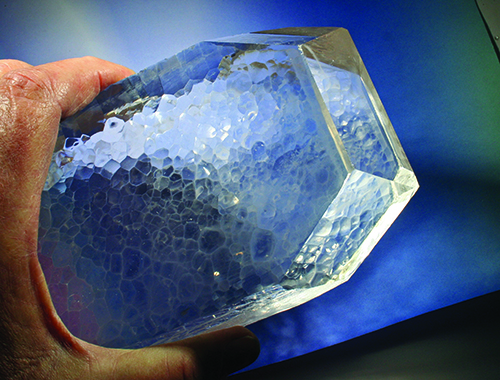

The crystal bars measure from ½ inch by ¾ inch by 8½ inches up to 2 inches by 4 inches by 8 inches. The ends do have the typical six-sided habit found in nature. The botryoidal surfaces are the growth surfaces, and the smooth ones are the crystal faces. I found them offered on eBay by seller lewisroberth by searching for the keywords “lab grown quartz crystals”.

Mapping Our the Process

I decided to make a project utilizing the characteristic perfect transparency of synthetic quartz. On the broken end of one of the synthetic quartz bars, I marked the outline of the overall cab, as well as the hole I would cut into it with the diamond ball bur. I used a 13 mm bur to make the larger hole, and then followed up with a 6 mm hole in the bottom of the larger hole.

The idea was to make a small hemisphere out of black jade and install it in the bottom of the larger hole, and make a larger carnelian hemisphere for the larger hole. After making the holes, I used my sphere-making cups on my flat lap to make the pieces that I would fit into the holes.

I mixed some epoxy 330 and set the hemispheres in place. After the epoxy had set, I shaped the synthetic piece into a hemisphere and polished it. At this point, I saw that, even with a diligent effort to keep them out of the epoxy, I still ended up with minute bubbles on the surfaces of the inserted pieces.

I believe these bubbles were caused by deterioration in the epoxy hardener due to its age.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.