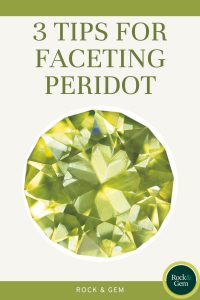

Faceting peridot can produce beautiful jewelry pieces and highlight the brilliance of this green gem. Lapidary, Jim Perkins, shares his peridot faceting design and three tips for cutting peridot.

“I like good brilliance and contrast with no extinction and no table reflection. However, optics is a matter of choosing your priorities and trade-offs. Sometimes you must give up something in order to make gains in other areas. That was especially true during the process of optimizing this design,” said Perkins.

Reflection Acceptance

To achieve proper brilliance and contrast, Perkins had to accept a slight table reflection. This is something physicists and fellow gem designers have said is common and nothing to worry about. By accepting the reflection, he was able to see that the gem fractures the light in a most satisfying way.

Feedback from other designers, gem cutters and connoisseurs about this design has been positive, which, Perkins said, reminds him to accept compliments and trust in the opinions of knowledgeable friends.

3 Keys to Cutting Peridot

1. Peridot is difficult to evaluate for inclusions. You can pick a piece you think is clean and after cutting and polishing you will find inclusions.

2. Some of the cleanest peridots seem to come from Pakistan and China. Although, Perkins also likes Arizona peridot.

3. Polishing can be difficult. Most cutters say to polish with aluminum oxide. Perkins has the best luck with a BATT LAP with 3,000 diamonds for pre-polishing and another BATT LAP with 100,000 diamonds. He uses paraffin-based candle oil as a lubricant for both BATT laps.

History of Techniques

By various accounts, the development of the round brilliant cut is the result of an evolution of techniques and the mathematical formulation of Marcel Tolkowsky, the author of Diamond Design.

Over the years, cutters of colored gems derived their cutting angles by extrapolating them from diamond cutters and the refractive index of the material they wanted to cut.

Perkins’ first exposure to gemstone cutting and design came when he was in seventh grade, during a meeting of the Akron, Ohio, Gem & Mineral Club and The Medina Gem & Mineral Society. A man named George Morse had built his own machinery, drew diagrams by hand and cut quartz gems.

Hooked on Faceting

“When I saw what he could do, I was hooked on faceting,” said Perkins, who immediately asked his parents for a machine to begin faceting work. However, it wouldn’t be until the early 1990s before Perkins purchased his own equipment and got down to work.

“I struggled to learn the [cutting] technique from my teacher and after I completed my first round cut brilliant, he told me to ‘go home and cut 25 more stones then bring them back and I’ll show you what you did wrong,’” said Perkins. “I looked at my stone and thought, this is pretty but there is something wrong optically. Over the years I would study in my spare time reading what I could. Eventually, I went to school at the lapidary school in Young-Harris Georgia.”

For nearly 30 years Perkins has been honing his craft and enjoying related exploration, achievement and an opportunity to share what he’s learned. One of the most beautiful aspects, as Perkins demonstrates, is the chance to always be learning.

This story about faceting peridot previously appeared in Rock & Gem magazine. Click here to subscribe! Story by Antoinette Rahn.